Reading Time: 4 minutes.

At Caster Concepts, we receive frequent inquiries from industries and manufacturers about moving exceptionally heavy loads. These typically range from 20,000 to 100,000 pounds. Safely and efficiently handling these loads requires expert solutions tailored to specific conditions.

Below, we address some common questions and considerations when selecting the right caster solutions for your application.

Choosing the right wheel starts with understanding your application’s environment and requirements. Here are some guidelines:

92A HPPT Polyurethane Tread

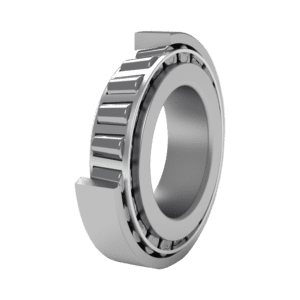

The wheel’s bearing is critical for supporting load and maneuverability.

| Sealed Ball Bearings | Tapered Roller Bearings | Straight Roller Bearings |

|

|

|

While these are our go-to bearings, they do require the user to maintain them by greasing on a set interval and checking for side-to-side play at least once per year. However, with proper care, tapered bearings can last years, even in harsh conditions.

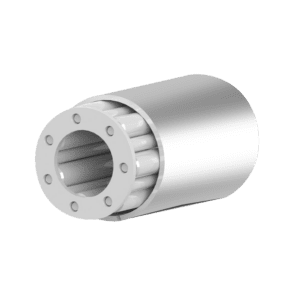

Swivel sections are essential for maneuverability and load management. Each type offers distinct benefits:

Kingpin-Style Casters

Kingpin-Style Casters Kingpinless Design

Kingpinless DesignTo enhance safety and efficiency, consider these customizable options:

Our team at Caster Concepts specializes in delivering innovative solutions for the heaviest and most challenging applications. From custom-engineered casters to maintenance-free designs, we’re here to ensure your operations move smoothly, safely, and efficiently.

Ready to get started? Contact us today to find the perfect caster for your heavy-load needs.