When you think of your bottom line, have you truly considered everything that goes into your expenses and earnings? Is employee injury having an impact on the amount of money spent on workers compensation claims? If this sounds familiar to you, it’s time to make a change. Force-reducing caster wheels not only reduce the risk of injury, but they can even enhance worker morale and productivity.

What Is a Force-Reducing Caster Wheel?

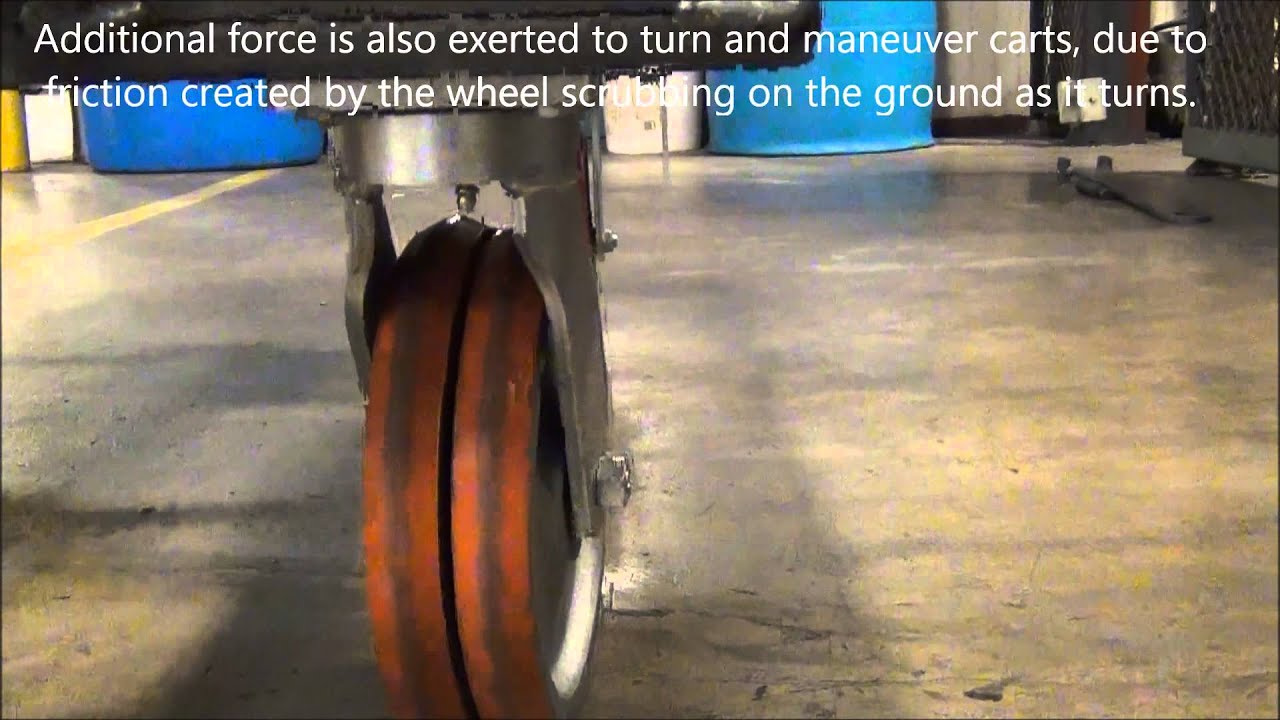

Casters are designed to allow workers to move loads of all sizes from one location to another. These casters come in various sizes and styles that are perfectly tailored to your facility and needs. Force-reducing caster wheels provide added benefits due in part to the materials used. For example, Twergo wheels by Caster Concepts utilize a parabolic wheel face that is designed to reduce the amount of exertion required to initiate movement as well as the amount of scrubbing that occurs while turning.

Independently Turning Multi-Wheel Design

Twergo wheels are some of the best force-reducing casters on the market today because they were specifically engineered with reduced friction and better ergonomics in mind. They have a dual- or triple-wheel design that offers more stability than single-wheel casters, and because each wheel turns independently of the next at any speed and in either direction, moving them around corners is a snap.

How Reducing Friction Can Make You More Money

It may seem a bit far-fetched to think that simply replacing the casters on your carts and racks can lead to increased revenue, but it’s actually pretty simple. There are several unique benefits of force-reducing caster wheels that you should take the time to consider.

- Less exertion – Workers can use less force to move the same size loads. Not only does this reduce the frequency of overexertion injuries, but it makes your workers’ lives easier and improves their overall morale.

- Bigger loads – Today’s force-reducing casters can carry loads of up to 4200 pounds per wheel, giving you the ability to move larger, heavier loads and save time – all without increasing the amount of exertion required to do it.

- Low maintenance – Today’s casters are also designed to be low-maintenance or even maintenance-free, which frees you from the financial burden of maintenance costs. You can also avoid downtime, which takes away from your ability to operate normally.

- Longevity – Force-reducing casters like Twergo wheels are especially designed to last for years. Joints and linkages are not exposed, the aluminum core resists rust and corrosion, and the sealed bearings do away with the need for frequent re-lubrication. When you replace your casters less frequently, there is less downtime, which boosts your earnings.

As you can see, your caster choice truly can save you money and help to enhance your bottom line. When you choose the right casters, you can save money on employee injuries, boost your production, reduce maintenance costs and downtime, and enjoy long-lasting casters that require less frequent replacement. All of these things can boost your revenue and keep your skilled employees on the job.